Heavy Duty Tape (Poron Foam)

XIAMEN ACOMA CHEMICAL MATERIALS CO.,LTD- Tube Chip Color:Full Color

- IP Rating:IP65

- Pixel Pitch:2.5mm

- Pixel Configuration:1R, 1G, 1B

- Display Function:Video Display

- Average Power Consumption:350W , m²

Base Info

- Model NO.:Heavy Duty Tape (Poron Foam)

- Pixel Density:10000 dot , m²

- Scanning Mode:Static Scan

- Display Type:LED Video Display

- Application:Stage Performance

- Certification:RoHS

- Transport Package:25

- Specification:25

- Trademark:ACOMA

- Origin:China

- Production Capacity:1000

Description

Basic Info.

Model NO. Heavy Duty Tape (Poron Foam) Pixel Density 10000 dot / m² Scanning Mode Static Scan Display Type LED Video Display Application Stage Performance Certification RoHS Transport Package 25 Specification 25 Trademark ACOMA Origin China Production Capacity 1000Product Description

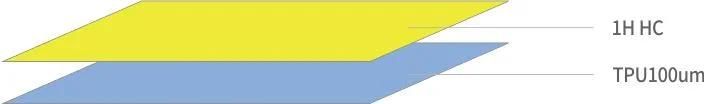

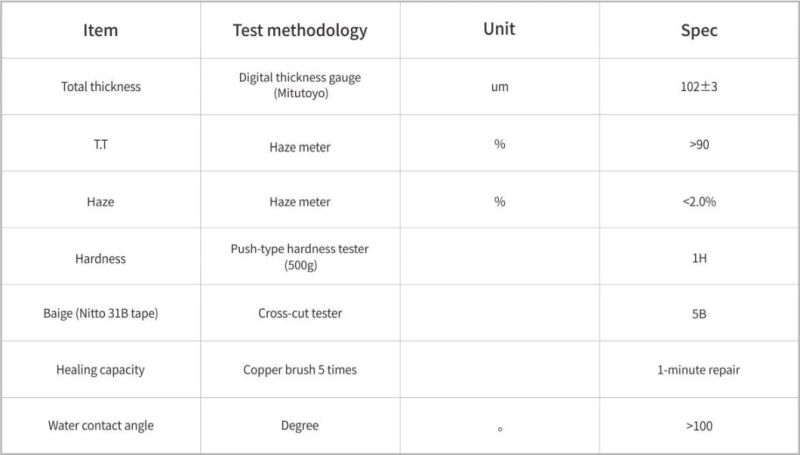

Self-healing HC/TPUProduct Description

• High glossy surface, self-healing in seconds, amazingly smooth effect.

• Super-hydrophobic and oleophobic, resistant to contamination by oil pen on the surface, excellent resistance to scratches by copper brushes, and self-healing from micro-scratches

• Significantly enhanced scratch and staining resistance of the film surface, with superior tensile properties.

Product Features

• High water contact angle

• Self-healing

Product Structure Diagram

Product Parameters

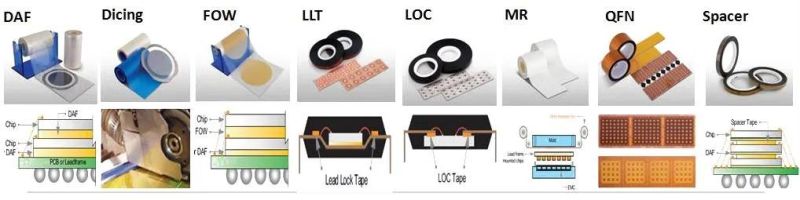

Precision coating bonding materials

Other Engineering Tapes

Product Description

Pre-engineering: Wafer fabrication

Post-engineering: Packaging

Product Features

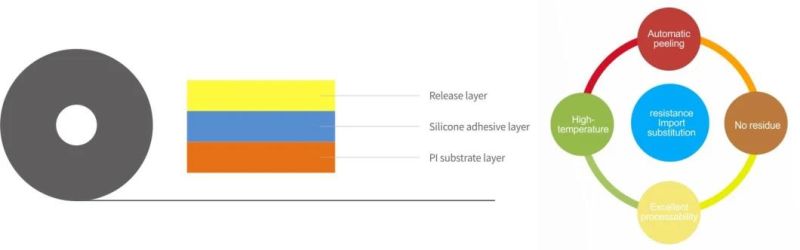

PI Termination Tape

Product Description

• Special PI termination tape for lithium/nickel/cadmium battery cell termination, pole ear insulation protection, and fixing.

Product Features

• Dust-free workshop production;

• Complete product specifications, moderate peel strength, and uniform unwinding force to meet the requirements of automated production lines;

• Polyimide film used as the substrate, excellent high-temperature resistance; acid and alkali resistant acrylic pressure-sensitive adhesive and color paste used, excellent electrolyte resistance

• Halogen content that meets the requirements of IEC 61249-21-21, SONY SS00259 (fifth edition), and EN-14582 battery directive.

Product Structure Diagram

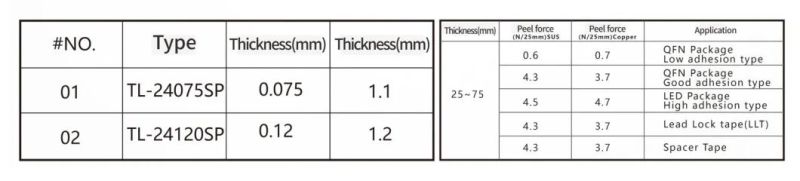

Product Parameters

PET Termination Tape

Product Description

• Special PET termination tape for lithium/nickel/cadmium battery cell termination, pole ear insulation protection, and fixing.

Product Features

• Dust-free workshop production;

• Complete product specifications, moderate peel strength, and uniform unwinding force to meet the requirements of automated production lines;

• Polyester film used as the substrate, excellent high-temperature resistance;

• Acid and alkali resistant acrylic pressure-sensitive adhesive and color paste used, excellent electrolyte resistance;

• Halogen content that meets the requirements of IEC 61249-2-21, SONY SS00259 (fifth edition), and EN-14582 battery directive.

Product Structure Diagram

Product Parameters

BOPP Termination Tape

Product Description

• Special BOPP termination tape for lithium/nickel/cadmium battery cell termination, pole ear insulation protection, and fixing.

Product Features

• Dust-free workshop production;

• Complete product specifications, moderate peel strength, and uniform unwinding force to meet the requirements of automated production lines;

• Polypropylene film used as the substrate, good applicability;

• Acid and alkali resistant acrylic pressure-sensitive adhesive and color paste used, excellent electrolyte resistance;

• Halogen content that meets the requirements of IEC 61249-2-21, SONY SS00259 (fifth edition), and EN-14582 battery directive.

Product Structure Diagram

Product Parameters

Semiconductor Packaging Engineering Tape

Product Description

• Heat-resistant re-peelable adhesive tape

• Excellent heat resistance, extensively applied in various fields.

Product Features

• Semi-conductivity (low resistivity), overload protection, stable temperature performance (130ºC/266F), excellent compatibility with various cables and conductors.

• Easy to stretch, good conformability on irregular surfaces.

• Resistant to solvents, UV rays, and moisture

• Customizable as per customer demand, strong viscosity before UV irradiation, which is significantly reduced after UV irradiation for easy peel-off

• Excellent machinability in wafer cutting and protection

Product Structure Diagram

Product Parameters

Highly Transparent Polyimide Film

Product Description

• Applicable to all smart terminal products using transparent AMOLED panels.

Product Features

• Class 1000 dust-free workshop production;

• Excellent optical properties (high transmittance), excellent high-temperature resistance, and high dimensional stability.

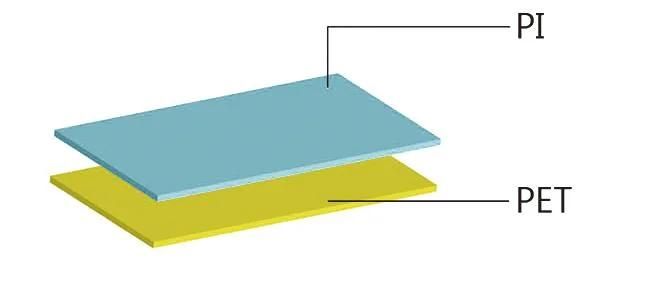

Product Structure Diagram

Product Parameters

Water Vapor Barrier Film

Product Description

• Water vapor barrier film used instead of glass for battery packaging in the flexible photovoltaic field in addition to packaging materials in CIGS, OPV and other thin-film photovoltaic cells;

• Packaging for OLED and QD film applications, infrared sensing, robotic sensing, smart wearable sensing, biomedical sensing.

Product Features

• Good transparency and environment-friendly. No decrease in barrier properties under high temperature and humidity. Excellent barrier properties at normal temperature, high weather resistance.

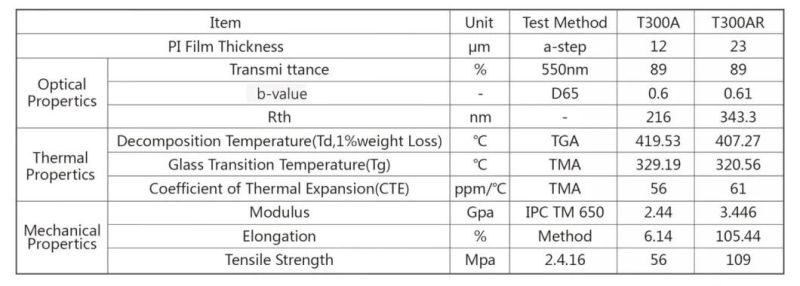

Product Structure Diagram

Double-sided tape for flexible display

Product Description

• The era of IoT requires the development and production of high-speed data transmission substrates to meet the information transmission from several MHz to GHz;

• FPCB for wireless charging.

Product Features

• PCB (Printed Circuit Board): signal transmission path for electronic products;

• FPCB (Flexible-PCB): (light and thin)/flexible;

• Flexible circuit boards linking electrical components and circuits, or linking circuits.

Blackout Double-sided Tape

Product Description

• Applicable to all mobile phones, Pads, and other products, fit on the adhesive tape between backlight and Cell.

Product Features

• Excellent light-shielding, re-workable, and processing performance;

• Coated with special colloid and thickened, with additional shockproof effect;

• Black side with a blackout ratio up to 99.9%, and the white side with a reflectance of 88.0%.

Product Structure Diagram

Product Parameters

Double-sided tape for light shading TSP back optical film

Product Description

• Applicable to all cell phones, Pads, and other productsfor bonding the tape between backlight and Cell.

Product Features

• Excellent optical rotation-resistance performance;

• Coated with special colloid and thickened for additional shock resistance;

• Re-workable;

• Excellent processability.

Product Structure Diagram

Product Parameters

Waterproof and dustproof optical double-sided tape

Product Description

• Suitable for cell phone Window Glass and Case bonding;

• Fixed use for Touch Panel and LCD module;

• Fixed use for cell phone camera/speaker/key.

Product Features

• Class 1000 dust-free workshop production;

• Excellent water resistance up to IP67 level;

• Excellent shock absorption;

• Excellent fit;

• Black and white colors. Black color also has the function of shading.

Product Structure Diagram

Product Parameters

AB Adhesive Double-sided Tape

Product Description

• Mainly applicable to tempered glass film

Product Features

• Excellent die-cutting performance, no excess glue;

• Made of optical PET film coated with high-performance silicone and UV-cured pressure-sensitive adhesive, ultra-transparent, ultra-thin, super automatic exhaus;

• Excellent optical performance, high light transmittance, fit without watermark, snow pattern, etc.;

• Excellent weather resistance, no foaming or glue residue after long-term use.

Product Structure Diagram

Product Parameters

Anti-blue light AB glue

Product Description

• Suitable for attaching tempered glass protective sticker to cell phone or PAD screens;

• Additionalfeatures of filtering high-energy short-wave blue light and ultraviolet light to reduce visual damage.

Product Features

• Excellent exhaust ability;

• Class 1000 dust-free workshop production, high cleanliness;

• Special technology and anti-impact treatment to effectively prevent the damage to LCD screen caused by the external force;

• Special silicone resin, with low viscosity automatic adsorption capacity;

• Special silicone resin, with low viscosity automatic adsorption capacity;

• High exhaust performance to prevent the generation of air bubbles effectively, high light transmittance (92%);

• Effectively filter up to 80% of short-wave blue light (380nm ~ 420nm);

• Good re-workable performance without degumming;

• Good cutting workability.

Product Structure Diagram

OCA optical tape

Product Description

• OCA optical tape, also known as optical adhesive, is a characteristic adhesive specially used for binding transparent optical components

Product Features

• Excellent die-cutting performance, no excess glue;

• Clarity, high light transmittance (full spectrum transmittance> 99%), high adhesion, high weather resistance, water resistance, high-temperature resistance, UV resistance, controlled thickness, uniform spacing;

• Excellent optical performance, high light transmittance, fit without watermark, snow pattern, no yellowing (yellow stain), peeling, or deterioration problems after long-term use;

Product Structure Diagram

Product Parameters

Heavy Duty Tape (Poron Foam)

Product Description

• Product Application: This product is applicable to the production or rework of touch screens, touch panels, flat-panel LEDs, liquid crystal modules, modules, batteries, metals, and plastic glass to remove OCA and LOCA residues and allow product reuse, without residual glue after tear-off

• Reliable super bonding, easy removal without residue when disassembly and repair are required, which significantly

improves its reworkability and can be operated perfectly even in a very narrow width

Product Features

• Easy removal without residual glue, no residual glue on the surface after tear-off (excellent removability) to protect the module from damage

• Excellent dustproof, anti-aging and anti-impact cushioning effects

• Super high adhesion and extensibility, no solvent, no odor.

• Superb initial strength and adhesion.

Product Structure Diagram

Product Parameters

VHB Tape

Product Description

• VHB tape has been successfully applied in many fields, such as metal curtain wall, glass curtain wall, elevator assembly, transportation market, etc.

• Main function: Structural fixing in place of traditional mechanical connection methods such as riveting and welding, UV and solvent resistance for outdoor use. Applications: Structural bonding of metals, plastics, glass, ceramics, and other materials.

Product Features

• Excellent aging resistance

• Nearly 100% bond strength retention

• Good adhesion, non-structural fixing of various materials, applicable to glass curtain wall, vehicle manufacturing, electronics, handicraft, and other industries, replacing traditional fixing methods such as screws and rivets to improve product aesthetics

• Excellent sealing performance, UV and solvent resistance for outdoor use.

• Excellent solvent resistance, softness, good fit, high tensile strength, shear strength, high-temperature resistance, stong adhesion

Product Structure Diagram

Product Parameters

Conductive Foam Tape

Product Description

• Various electronic components, conductive grounding, electromagnetic shielding, and electrostatic discharge (ESD);

• Easy to fix and bond, strong and firm adhesion upon use;

Product Features

• Precise coating control technology, stable product thickness, and mechanical properties, etc.;

• Conductive foam substrate used, coated with conductive acrylic glue;

• The product has three-dimensional conductivity, as well as foam bonding and cushioning properties.

Product Structure Diagram

Product Parameters

Precision coating protective materials

Self-healing Protective Film

Product Description

• The self-healing film features high viscosity, high elasticity, and cushioning for protection against scratches and self-healing.

Product Features

• Perfectly repair screen scratches and provide full-range protection of the screen

• Excellent anti-bubble function, washable and reusable

• Special optical characteristics to prevent ultraviolet and infrared penetration and extend the service life of equipment

Product Structure Diagram

HF acid-resistant protective film

Product Description

• Applicable to processes such as glass etching, secondary strengthening, cutting ...

Product Features

• Excellent adhesion, re-workable performance, and good covering;

• 150um substrate thickness can offer good support for cutting, laminating and other processing.

Product Structure Diagram

Product Parameters

Protective film for wafer dicing

Product Description

• Suitable for surface protection when cutting LED semiconductor chips;

• Used to prevent stainless steel plates, aluminum plates, and nameplates from being damaged during processing;

• Used to protect materials such as glass and aluminum window frames.

Product Features

• Long-lasting adhesion without adhesive residue;

• Resistant to high temperatures;

• Excellent process ability.

Product Structure Diagram

Product Parameters

Printable LCD protective film

Product Description

• Applicable to all cell phones, Pads, and other products to protect LCD screens during shipment.

Product Features

• Excellent surface printability;

• Re-workable;

• Special surface treatment to reflectinga better texture and increase the added value of the product.

Product Structure Diagram

Product Parameters

PET Waste Discharge Film

Product Description

• PET waste discharge film is mainly used for die-cutting waste discharge;

• Mainly applicable to the surface protection of acrylic, PC, PET and other sheets, high-gloss stainless steel plates, aluminum plates, gold-plated sheets, electroplated keypad, high-gloss ABS + PC injection molding products.

Product Features

• Class 1000 dust-free workshop production;

• PP and PET materials with low to high viscosity, complete specifications, no bubbles, suitable for surface protection.

Product Structure Diagram

Product Parameters

PET Optical Protective Film

Product Description

• PET protective film is mainly used for touch screen mobile phone/tablet anti-scratch and anti-fingerprint protection as well as mobile phone lens, touch screen, and display panel processing protection.

Product Features

• Class 1000 dust-free workshop production;

• Minimal variation in peel force, easy to fit and peel;

• Surface with special functions such as anti-glare, anti-reflection, and printability through special layers.

Product Structure Diagram

Product Parameters

CPP Optical Protective Film

Product Description

• CPP protective film is mainly used for the protection of prism sheets, diffusers, light guide plates, notebook cases, and precision optical glass in LCD and LED backlight module.

Product Features

• Class 1000 dust-free workshop production;

• Protective film for the positive protection of brightness enhancement film (BEF) and diffuser, products with three peeling forces available, for large, medium and small size BEF and diffuser film, can replace Nitto L-73 series products;

• Little change in the peeling force after baking at high temperature, no residue, excellent protection of product surface.

Product Structure Diagram

Product Parameters

CPE optical protective film

Product Description

• Suitable for protection of LED lens, light guide plates, and optical glass in LED backlight modules.

Product Features

• Certain stiffness and high-temperature resistance, can be used under the operating environment of 135ºC;

• Glueless, small variation of peeling force, easy to fit and peel;

• Suitable for products with high thickness uniformity and high crystal point requirements.

Product Structure Diagram

Product Parameters

PE optical protective film

Product Description

• Suitable for LCD light guide plates, diffuser film cutting, acrylic, PC, PET, glass sheet, touch screen glass, and high-brightness injection molding shell protection;

• Antistatic type is mainly used for the protection of high-precision electronic parts such as LED backlight modules and light guide plates.

Product Features

• Provide customized peeling force design according to the surface roughness of the attached object;

• Small variation of peeling force, easy to fit and peel;

• Thickness uniformity within ± 4%.

Product Structure Diagram

Product Parameters

Release Film for OLED Die-cutting

Product Description

• Excellent ultralight peeling effect.

Product Features

• Extraordinary stability.

The product has passed the ROHS 2.0 test. Substrate thickness can be customized as per customer requirements.

Product Structure Diagram

Product Parameters

Anti-static Release Film

Product Description

• Transparent anti-static layer (non-polythiophene) in the real sense that presents excellent resistance to aging even in extreme environments;

• Developed for OCA products specifically.

Substrate thickness can be customized as per customer requirements:

Product Features

• Extraordinary stability;

• Excellent surface flatness;

Product Structure Diagram

OCA optical release film

Product Description

• Applicable to OCA optical adhesive products, which requires that the OCA release film must be an optical grade original film, with light transmittance > 91%

• Production in a clean environment requiired

Product Features

• High speed;

• Stability;

• Atmospheric exposure;

• Electrostatics prevention.

Product Structure Diagram

Product Parameters

MLCC Release Film

Product Description

• MLCC release film is the crucial material of MLCC (Multilayer Ceramic Chip Capacitor), the core component to ensure the stable current of smartphone display and camera lens

Product Features

• Adjustable peel strength

• Excellent flatness

• Extraordinary peel force stability

Product Structure Diagram

Product Parameters

Fluorine Release Film

Product Description

• Fluorine release film, also known as fluorine film, is mainly used for blocking sticky objects such as silicone and PI tapes. During production, storage, or transportation, fluorine release film has the effect of protecting the adhesive from contamination and transformation.

• Widely used in tapes or carriers with adhesive products.

Product Features

• Adjustable peel strength

• Good economy

• Extraordinary stability

Product Structure Diagram

Product Parameters

Super Light Release Film

Product Description

• Super light release film is a common material used for thermal transfer, with the substrate of PET coated with silicone oil, also known as silicone oil film. Conventional thickness: 25um ~ 150um. It can be divided into cold/hot tear and matte surface, after anti-static and anti-scratch treatment, with excellent absorption and fit.

Product Features

• Excellent peel strength

• Good transparency

• Extraordinary stability

Product Structure Diagram

Product Parameters

UV Viscosity Reducing Film

Product Description

• UV viscosity reducing film, also known as UV viscosity loss/reducing tape, is UV viscosity reducing tape formed by coating special film with UV viscosity reducing adhesive. It presents a high adhesion (10 ~ 20N/inch) in the normal state, which, however, decreases sharply (below 0.5N/inch) after UV irradiation.

• Great Rich (Tongli) can produce various substrates PO/PET, and viscosity reducing tapes with different thickness to implement different initial adhesion and meet the requirements of customers for different specifications and performance.

Product Features

• High adhesion during cutting and grinding to ensure that the chips do not scatter, preventing scratches and abrasions, etc.

• Quick response to UV irradiation, sharp adhesion reduction, easy peeling

• No pollution to the protected object after peeling, no residue

Product Structure Diagram

Product Parameters

Release Film for Polarizer

Product Description

• The surface of the release film for polarizer has been specially treated and added with a layer different from the film material itself to avoid sticking to certain specific materials.

• It is more convenient to remove after users are done using this layer of film, reducing the probability of damage to the produced machine

Product Features

• Excellent peel strength

• Good transparency

• Extraordinary stability

Product Structure Diagram

Product Parameters

Polymer film materials

FOOD PACKING SERIES

CPP,CPE CASTING FILM SERIES

| Table India type CPP | The film has more adavantages than the common CPP film: Can be printed directly; Has high mechanical properties; Excellent flatness; High transparency, is similar to the glass; It's friction coefficient is less than 0.2. Mainly used in the extermal packing material for noodles, napkins and so on. |

| High-temperature cooking type CPP | High temperature steaming film: On the base of the common composite film, it can be used for cooking and steaming at around 125 degrees centigrade. The high-temperature steaming and cooking film developed by the Company can function properly at 135 degrees centigrade without any deforming or damage after steaming for 45 minutes. Compared with films of the same kind film made by foreign countries, it can save too much cost. Therefore, it is widely used in vacuum food packing. |

| Antistatic type CPP | Anti-static CPP film: It enjoys all the features of the common film as well as the anti-static features that common films do not have. It is mainly used for packing powdered, melectronic and medical products. |

| Toughening type CPP | The film is mainly used for clothing packaging, with super toughness and high transparency. |

| Flow delay CPE films | CPE film, different from the PE blown film in technical process, this film is produced by casting, has obviously advantages in the flatness, transparence and even compared with the PE blown film. |

CPP,CPE CASTING FILM SERIES

| PE-A-P tablet packaging film | It applies to automatic packing. In time of packing the finished products, it can insure a good packing positioning so as to avoid the position deviation which may damage the medicines. |

| PE-Y tablet packaging film | The film is easy to tear horizontally. Therefore, the medicine packing can be opened easily and the medicine can be conveniently taken out. Moreover, it maintains a good heat-seal strength as well as comfortable soft feeling. |

| PE condom membrane | The film is mainly used as the external film for packing condoms. It is different from the common film because it is anti-oil, anti-penetration,hard to tear and damage. |

PE BASE MATERIAL FILM SERIES

| PE no crystal point protective film substrate | Under the control of the dust-free system, the advanced equipment has produced the protective film substrate without crystal points, widely used in protecting the surface of the color steel plates, stainless steel plates, house appliances, furniture and plastic plates, etc. |

| Without solvent composite materials | The composite materials produced by the European technologies and the Italian energy-saving equipment, are mainly used to the material like BOPP,PETP,LDPE,LLDPE,OPA,NY,HL,CPP,COEX,FILM,PAPER, and etc. |

| PE shielding, aluminum foil composite matrix membrane | This kind of film is used for packing the electronic products. It can be brought under direct anti-static treatment or treated by the customers. The characteristics lies in the fine-adjusting of the formula to promote its intensity and heat seal strength. Performance of the openings is excellent. Control of the planeness and crystal points can all go through practical tests. |

FOOD PACKING SERIES

| PE-T hot sealing can peel easy tear film | After heat-sealing treatment, the film enjoys good heat seal strength. It accords with the sealing requirements for medicines and can be completed and entirely separated in use without being torn, even for long-term storage. For example, the film can be used in the packing of the suppository medicines. |

| PE oil coated | This film has such god virtues as non-penetration, non-toxicity, smell-free, anti-oil and anti-pollution, good sealing strength, low temperature heat-sealing and good peelability. It applies to the high-speed automatic packing production lines and accords with the hygienic standards for food packing. The oil packing film of TONGLI is also used in the instant-noodle industry, for packing the oil ingredients and sauce packets for many famous enterprises, for example, Master Kang, Hualong and White Elephant. |

| PE antistatic packaging film | The anti-static PE film produced by TONGLI Company is high in transparency, low-temperature heat-sealing, superior mechanic performance and easy-opening. It is often used in packing the Monosodium Glutamate, milk powder and bean milk powder as well as other dairy food and medicines. It is also used as the internal packing material for the powdered chemical reagents, especially for composting with aluminum. Moreover, it has very good anti-static effect in packing the common industrial electronic and electrical products. |